FAQs

AFTER INSTALLATION

- Do not attempt to completely open the door unless you have read the operating manual and followed the instructions therein.

- Expansion gaps must be lift in floor screeds and timber floor finishes so the door threshold is not affected.

- Protect finished surfaces from cement and any other forms of chemical which can discolour the finished surface.

CARE AND MAINTENANCE

- Doors should always be opened and closed in accordance with operating instructions. If you have misplaced the operating instructions, please contact us and we’ll be happy to replace.

- The best method of cleaning is by regular washing of the door using a solution of warm water and mild detergent. All surfaces should be cleaned using a soft cloth or sponge, using nothing harsher than natural bristle brushes. Cleaning of window sections etc. can be conveniently carried out at the same time as glazing cleaning).

- Stubborn marks on the powder coating may be removed with methylated spirits. Refer to the table for recommended cleaning intervals.

| FINISH/LOCATION | CLEANING INTERVAL |

|---|---|

| Normal environment with standard RAL coating or Anodise finish | Clean and check every 6 months |

| Marine coating (or located above 1000m) | Clean and check every month |

| Industrial environment | Clean and check every month |

| Swimming and leisure pools | Clean and check every month |

HOW TO SURVEY A DOOR APERTURE

At Spitfire Doors we want to make it easy for you to choose and buy your aluminium entrance door. Here, we’ve put together some guidance and points to consider before ordering your door.

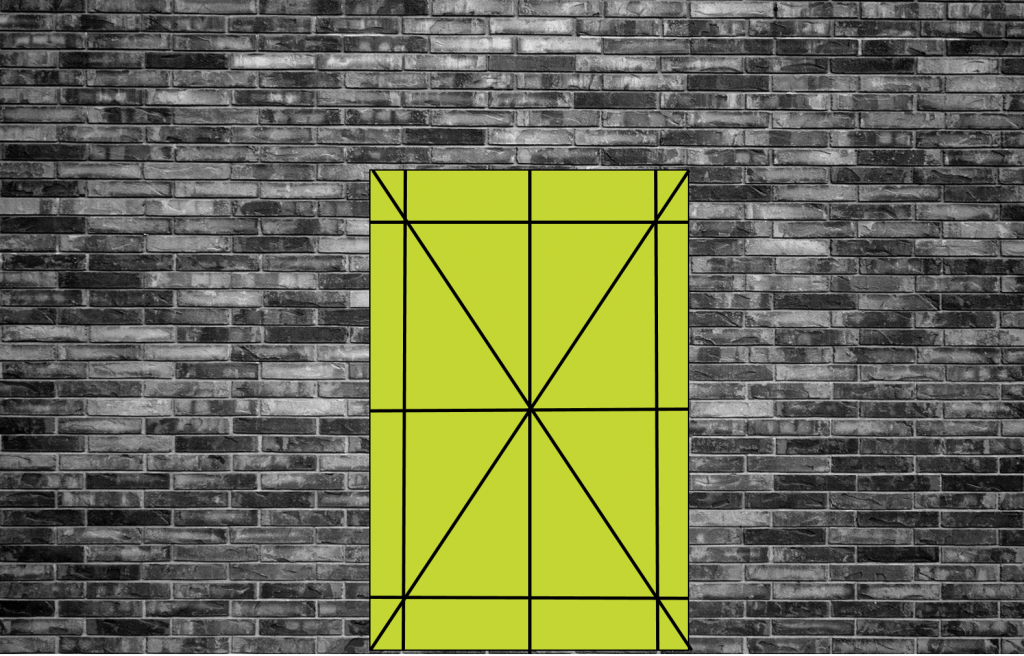

HOW TO SURVEY A DOOR APERTURE

Measure the width and height taking 3 measurements for each (see picture).

Take diagonal measurements to show if door aperture is square

Use the smallest width and height for the manufacturing size

Always deduct this fitting tolerance before placing your door order

CILLS AND THRESHOLDS

- Will you need a sub-cill?

- To avoid trip hazards, it is good practice to use a low threshold for an entrance door

- When calculating the size, depth and projection of the sub-cill ensure there is adequate overhang of at least 50mm from the face of the building

- Decide how the sub-cill will be fitted, taking into account any features such as horns

- Following installation, plan how any making good will be carried out.

REVEALS AND HINGES

- Note any difference between internal and external reveal sizes and check the door leaf will not be impeded by plaster, tiles or carpet when opening or closing.

- We recommend taking a measurement between the skirting boards since this is usually the narrowest point of any door opening.

- When you have calculated any difference between the internal and the external sizes, check if any part of the frame will be behind the plaster.

- Also ensure the hinges will not be too close to the plaster line or that the glazing will not disappear behind the plaster line.

- If there are foot mats behind the door on the inside, ensure the door leaf will not bind on the flooring when it opens.

- Will the floor covering change in future? This may have an impact on the opening of the door.

ASK US FOR ADVICE – WE’RE HAPPY TO HELP

Call the Spitfire Doors team for advice about appropriate add-ons, cills, thresholds and furniture options.

HOW TO DETERMINE THE MANUFACTURING SIZE

With aluminium framing you should deduct 12mm from the smallest of your aperture measurements. When calculating height deductions make allowance for the thickness of any sealant or mortar bed at the sub-cill. Ensure the thickness of the internal plaster does not hide or obscure the frame or hinges. If so, order the appropriate add-on.

- Is there any evidence of asbestos that may need to be removed or disturbed?

- Is the aperture square and even to within 5mm height and width and 10mm diagonals?

- Will any loads be carried by the building and not the doorset?

- Is there a proper damp proof membrane in place?

- Has the size of the sub-cill and method of fixing been determined?

- Has the hinge side been determined when viewed from outside?

- Will door function properly without binding on the floor?

- Will the door hinges function without being fouled by plaster?

- Is the size and configuration within the Spitfire Doors manufacturing limits?

- Is the door design specification suitable for the location?

- Will the new door installation comply with Building Regulations?

- Has any additional hardware been specified?

- Is the access for installation safe?

- Has the fixing method been determined?

- Has the extent of making good been agreed with the customer?

- Is the door set being installed in a coastal or chemical environment?

DO

- Use the mildest possible cleaning agents

- Use plastic or wood tools

- Follow any polishing lines if you use slightly abrasive cleaners

- Rinse thoroughly

- Wipe dry

DON’T

- Use steel or metal scrapers as they will cause rust spots

- Allow chemicals, bleaches or chlorides to remain on the steel for more than a minute

| Problem | Action | Note |

|---|---|---|

| Routine cleaning | Soap, ammonia or detergent with warm water. | For use on all finishes |

| Fingerprints | Soap and warm water or organic solvent | For use on all finishes |

| Oil or grease marks | Alcohol or trichlorethen thinners | Use carefully |

| Rust or corrosion | Oxalic acid | Apply by swab and allow to stand for 10 minutes, then rinse |

Powder coating is a dry finishing process used in many industries where a high quality, long lasting finish is required. We use it at Spitfire because it provides a high-quality, durable finish and the process is relatively environmentally friendly. This advanced process is available in an almost limitless range of colours and textures and technological advances have resulted in exceptional performance properties which allows us to give a long warranty on our finishes, with confidence.

Durability of Powder Coating

Because powder coated finishes are so tough they are used on thousands of products we come into contact with every day. Powder coating is used to protect equipment like earthmoving trucks and aircraft as well as everyday household products, that we use daily. This exceptional process is more durable than a liquid paint finish and is much more resistant to fading or degradation when faced by attack from impact, moisture, chemicals, ultraviolet light or extreme weather conditions. This also reduces the risk of scratches, chips and corrosion. In summary, a powder coated finish looks great, is consistent if applied professionally and will last a long, long time.

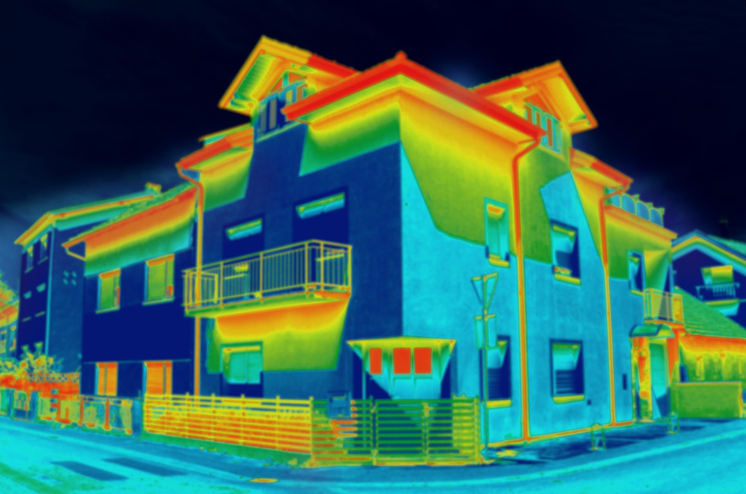

U-values, technically termed heat transfer coefficients, are used to measure how effective building products are at preventing heat being lost from inside a building.

The lower the U-value of a door, the more slowly heat is able to transmit through it, and so the better the door performs as an insulator.

Therefore, less energy is required to heat your home as heat is retained for longer. As energy prices increase there is greater awareness of the costs, and performance measures such as U-values are now seen as very important.

Across Europe, Building Control Authorities are stipulating that lower and lower U-values must be are achieved. This means that building design has had to change to accommodate these lower values, which particularly affects doors and windows.

U-values are measured in watts per square metre, per degree Kelvin (W/m²K). For example, if we take a double glazed window with a U-value of 2.6; for every degree difference in temperature between the inside and outside of the window, 2.6 watts will be transmitted every square meter. The minimum requirement for doors in England and Wales is currently 1.8 W/m²K and in Scotland 1.6 W/m²K.

The whole U-value issue is scarcely mentioned by fibreglass and uPVC Composite Door manufacturers because in almost all cases the composition of their doors prevents them improving upon the minimum standard. Timber is a very poor insulator and wooden doors

struggle to attain any meaningful U-value.

Spitfire Aluminium Doors easily outperform composite and timber doors with U-values as low as 0.74 W/m²K.

The lower the U-value of a door, the more slowly heat is able to transmit through it.